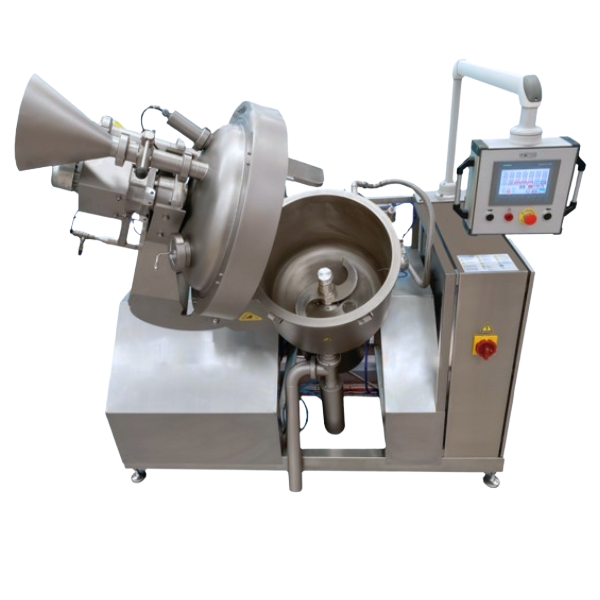

PROFESSIONAL ROTARY OVENS - Convection and Rotation Cooking System

PROFESSIONAL ROTARY OVENS

Fast and Even Cooking, Designed for Demanding Professionals.

Our professional rotary ovens are designed for both industrial and artisanal bakeries. The forced convection system combined with the rotating rack guarantees perfectly even baking, a golden crust, and an open crumb for all your bread products.

Type: Rotary oven with forced convection

Application: Industrial bakery, pastry shop, viennoiserie

Advantage: Even cooking with rotation for uniform distribution

Main characteristics of Rotary Ovens

- Forced convection cooking with continuous rack rotation

- Burner and heat exchanger positioned at the front for side-by-side installation

- Balanced hot air convection with adjustable louvered ventilation

- Controlled steam system for optimal rising

- High-performance thermal insulation made of 80 mm rock wool

- Constructed entirely of AISI 304 stainless steel

- Certifications: CE, NF, UL, compliance with food safety standards

- PID digital controller with touchscreen and cycle programming

- Adjustable steam injection system with recovery

- Double doors with silicone seals and thermal glazing

Full description

Oven with a rotating rack designed to meet the intensive needs of artisan bakers and pastry chefs. Its fan-assisted baking speeds up cycles, while the rotating rack ensures perfect uniformity, whether for bread or the most delicate pastries.

Designed for everyday use, it comes standard with a trolley attachment at the top for easy floor cleaning. To further optimize ergonomics, a platform for trolleys with a lower attachment is available as an option, facilitating loading and unloading.

Technical data for Rotary Kilns

| Model | Rotating Oven 80 x 120 | Rotary Oven 60 x 80 | Rotating Oven 60 x 40 |

|---|---|---|---|

| Cooking capacity | 40-60 baguettes/cycle | 25-35 baguettes/cycle | 15-20 baguettes/cycle |

| Dimensions chariot (cm) | 80 x 120 | 60 x 80 | 60 x 40 |

| Temperature range | 50°C - 300°C | 50°C - 300°C | 50°C - 300°C |

| Temperature accuracy | ±2°C | ±2°C | ±2°C |

| Type of heating | Natural gas/propane | Natural gas/propane | Natural gas/propane/electric |

| Thermal power | 85,000 kcal/h | 60,000 kcal/h | 35,000 kcal/h |

| Rotation speed | 4-12 revolutions/hour | 4-12 revolutions/hour | 4-12 revolutions/hour |

| Gas consumption | 8-10 m³/h | 5-7 m³/h | 3-4 m³/h |

| Total weight | 850 kg | 620 kg | 380 kg |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| Mirror polished stainless steel body | Automatic programming with memory |

| Electric rotation of the trolley | Integrated refrigeration system |

| PID controller with touchscreen | Integrated weighing system with load cells |

| Automatic steam injection | Hydraulic tilting for unloading the kiln |

| Cycle programming (50 profiles) | Network interface and remote monitoring |

| Automatic catalytic cleaning | Heat recovery system |

| Recording of HACCP parameters | Full traceability with barcode |

| Thermal protection and integrated safety | Complete hygienic fairing |

FEATURES DETAILS

Rotation and Convection System

The continuous rotation of the trolley, combined with forced convection, ensures even heat distribution across all products. This technology eliminates cold spots and hot spots, guaranteeing consistent cooking and perfect crust browning throughout the entire load.

Precise Steam Control

The precisely regulated steam injection system allows for optimal humidity control during the first few minutes of baking. This is essential for the bread to rise, achieve a shiny, thin crust, and promote the formation of even air pockets in the crumb.

Energy Saving

High-performance thermal insulation (80 mm of rock wool) and a heat recovery system significantly reduce energy consumption. The compact design allows for the side-by-side installation of multiple ovens, optimizing space and installation costs.

Areas of application

Our rotary ovens are suitable for various applications in the baking and pastry industry:

- Industrial bakery - Production of traditional breads, baguettes, specialty breads

- Pastries - Croissants, chocolate croissants, brioches

- Pastries - Leavened pastries, babas, savarins

- Specialty breads - Wholemeal, multigrain, gluten-free

- Artisan bakery - Medium and large capacity production

Advantages of rotary cooking

Superior product quality

Even baking ensures uniform browning, a crispy crust, and a perfectly open crumb. The absence of hot spots eliminates the risk of burning and guarantees optimal texture for all baked goods.

Increased productivity

The automatic trolley rotation reduces handling and speeds up loading and unloading. The large baking capacity and programmable cycles optimize hourly output and overall productivity.

Versatility and adaptability

Rotary ovens are suitable for a wide range of products, from traditional baguettes to delicate pastries. Multiple programming options allow for the storage of specific recipes for each product, guaranteeing perfect consistency.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.