Professional spiral mixers - Gentle kneading system that preserves the gluten structure

PROFESSIONAL SPIRAL MIXERS

Gentle kneading preserves the gluten structure for airy, high-quality dough.

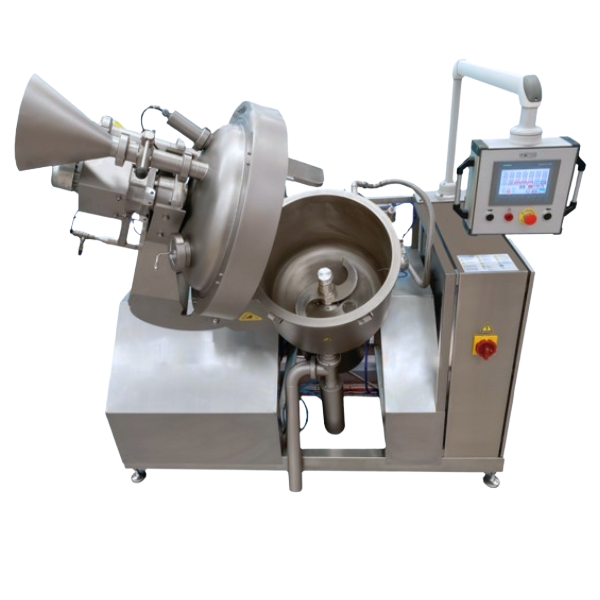

Our professional spiral mixers are designed for both industrial and artisanal bakeries. The gentle kneading system with spiral motion ensures optimal preservation of gluten structure, controlled fermentation, and a perfect texture for all your baked goods.

Type: Fixed-bowl spiral mixer

Application: Industrial bakery, pastry shop, viennoiserie

Advantage: Gentle kneading preserves the gluten structure

Main features of spiral mixers

- Gentle kneading using a spiral motion preserves the gluten structure

- Fixed stainless steel tank with stainless steel spiral

- Two-speed motor for spiral and bowl with transmission via pulleys and V-belts

- Bowl push roller for easy handling

- Front control with two timers and automatic speed change

- Painted steel structure raised on 4 adjustable feet

- Certifications: CE, compliance with food safety standards

- Adjustable working time with automatic switching from 1st to 2nd speed

- Stainless steel protective guard for safety

- Ergonomic design for easy loading and unloading

Full description

Spiral mixer designed to meet the intensive needs of artisan bakers and pastry chefs. Its gentle kneading system preserves the gluten structure while ensuring optimal dough development, guaranteeing airy finished products with a perfect texture.

Designed for everyday use, it features a fixed stainless steel tank and a robust spiral for exceptional durability. To further optimize your productivity, different capacities are available to suit your production volume.

Technical data for Spiral Mixers - START EVO range

| MODEL | START EVO 35 | START EVO 50 | START EVO 60 | START EVO 80 | START EVO 120 | START EVO 160 |

|---|---|---|---|---|---|---|

| Dough capacity (min./max.) *kg | 8/35 | 8/50 | 15/60 | 15/80 | 20/120 | 20/160 |

| Tank volume (L) | 50 | 75 | 100 | 120 | 205 | 240 |

| Motor power 1st/2nd speed (kW) | 0.8/1.6 | 0.8/1.6 | 1.5/3 | 1.5/3 | 3/5.2 | 3/5.2 |

| Height from tank edge (mm) | 680 | 710 | 780 | 790 | 835 | 900 |

| Total depth (mm) | 875 | 945 | 1030 | 1100 | 1240 | 1240 |

| Total width (mm) | 550 | 565 | 645 | 700 | 845 | 845 |

| Total height (mm) | 1100 | 1100 | 1250 | 1250 | 1390 | 1390 |

| Net weight (kg) | 170 | 190 | 255 | 260 | 395 | 400 |

*: Capacity based on the percentage of liquid/flour = 60%

Dough Mixer Models

| Model | 130KG Self-Tilting Spiral Mixer | Spiral Dough Mixer with Fixed Bowl, 80KG | SM70 Spiral Dough Mixer | SM50 Spiral Dough Mixer | Fixed Bowl, Fork, Dough Mixer |

|---|---|---|---|---|---|

| Brand | TEKNO STAMAP | TEKNO STAMAP | 3F ALIMACCHINE | 3F ALIMACCHINE | MIXER |

| Capacity (kg) | 130 | 80 | 70 | 50 | Variable depending on the model |

| Kind | Self-tilting | Fixed bowl | Spiral | Spiral | Fork |

| Application | For divider | Bakery | Bakery | Bakery | Bakery |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| Painted steel rack raised off the ground on 4 adjustable feet | Improved tool speed (205 rpm) |

| Bowl, spiral, contrast column and stainless steel guard | Machine mounted on wheels (2 fixed rear wheels and 1 swiveling front wheel) |

| A two-speed motor for spiral and bowl | Stainless steel bowl lid with polyethylene airtight rim |

| The movement is transmitted by pulleys and trapezoidal belts | Special voltage/frequency: 230/50/3 220/60/3 380/60/3 |

| Bowl push roller | Packed in a wooden crate |

| Front control with two timers | Specialized cleaning accessories |

| Adjustable working time with automatic switching from 1st to 2nd speed | Integrated refrigeration system for temperature control |

| Thermal protection and integrated safety | Advanced digital interface with program memory |

FEATURES DETAILS

Gentle Spiral Kneading System

The continuous spiral motion combined with controlled speed ensures optimal gluten development without tearing. This technology preserves the molecular structure of the dough, guaranteeing controlled fermentation and a perfect airy texture for all types of breads and pastries.

Precise Speed Control

The two-speed system with automatic switching allows for optimal control of the kneading process. The first speed ensures the homogeneous mixing of ingredients, while the second speed perfectly develops the gluten network without overheating the dough.

Energy Saving and Sustainability

The pulley and V-belt drive with an oil-bath geared motor significantly reduces energy consumption. The robust steel and stainless steel construction ensures a long service life, even under intensive use.

Areas of application

Our spiral mixers are suitable for various applications in the baking and pastry industry:

- Artisan bakery - Kneading traditional bread dough, baguettes, specialty breads

- Pastries - Croissant dough, chocolate croissants, brioches

- Pastry making - Dough for babas, savarins, leavened doughs

- Specialty breads - Wholemeal, multigrain, gluten-free

- Industrial bakery - Medium and large capacity production

- Pizzeria - Pizza dough with varying hydration levels

Advantages of spiral kneading

Superior quality of the final product

Gentle kneading ensures a consistent airy texture, a crispy crust, and a light, elastic crumb. Preserving the gluten network ensures better retention of fermentation gases and optimal development during baking.

Increased productivity

The various available capacities adapt to all production volumes. The efficient kneading system reduces cycle times while maintaining consistent quality, optimizing hourly output and overall productivity.

Versatility and adaptability

Spiral mixers are suitable for a wide range of doughs, from firm to highly hydrated. Their modular design allows for customized configurations to meet the specific needs of each bakery or pastry shop.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.