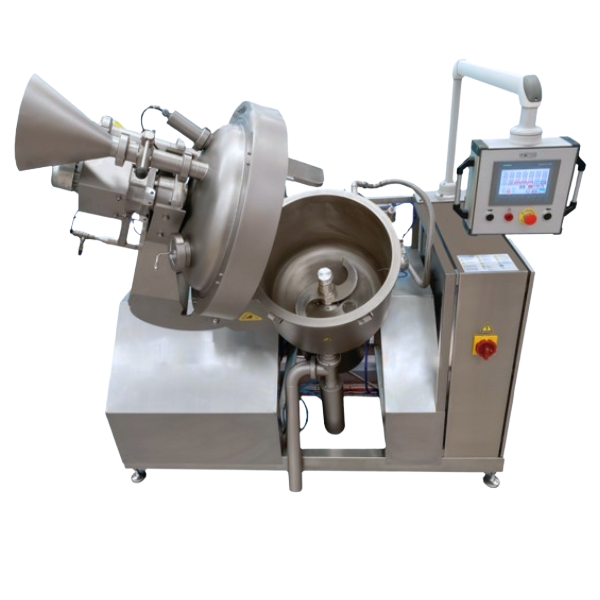

Industrial flour sifter - High-performance sifting and aeration system

Industrial Flour Sifters

Advanced sieving and aeration technology for optimal flour quality

Our industrial flour sifters are designed to efficiently remove all impurities while oxygenating the flour to improve its baking properties. The vibrating sifting system and integrated aeration ensure perfectly sifted, aerated flour, ready for producing high-quality dough.

Type: Vibrating flour sifters with aeration system

Application: Industrial bakeries, flour mills, cereal industries

Advantage: Complete removal of impurities and optimal oxygenation

Main features of flour sifters

- High-efficiency vibrating sieving system with interchangeable meshes

- Production capacity: 50 kg every 6-8 minutes (standard model)

- Production capacity: 100 kg every 5 minutes (high-performance model)

- Integrated aeration system to oxygenate the flour and improve its properties

- Effective removal of impurities, foreign bodies and agglomerates

- Constructed entirely of AISI 304 or 316L stainless steel

- Mobility ensured by wheels with a locking system

- Height-adjustable rotating outlet (standard height: 104 cm)

- Bilateral access for easy inspection and maintenance

- Certifications: CE, NSF, European food safety standards

Full description

Our industrial flour sifters represent excellence in flour preparation for the baking and cereal industries. Designed to ensure uniform and efficient sifting, they remove all impurities while oxygenating the flour to improve its properties.

Vibrating sieving technology allows for the precise separation of unwanted particles while preserving the intrinsic qualities of the flour. Integrated aeration improves flour oxygenation, resulting in a lighter, more homogeneous dough of higher quality.

The modular and mobile design facilitates integration into existing production lines, while food-grade materials ensure safety and hygiene throughout the process.

Technical data for Flour Sifters

| Setting | Specifications |

|---|---|

| Machine type | Vibrating flour sifter with aeration |

| Sieving capacity (standard model) | 50 kg / 6-8 minutes |

| Sieving capacity (high-performance model) | 100 kg / 5 minutes |

| Sieve mesh diameter | 0.1mm to 2mm (standard 0.8mm) |

| Type of movement | Circular vibration with adjustable amplitude |

| Vibrator motor power | 0.75 - 2.2 kW depending on the model |

| Vibration speed | 1400 - 2800 rpm (adjustable) |

| Materials in contact | AISI 304/316L, food-grade silicone seals |

| Exit height | 104 cm (adjustable as needed) |

| Dimensions (L x W x H) | 1200 x 800 x 1600 mm (standard model) |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| Mirror polished stainless steel body | Integrated dust extraction system |

| Adjustable amplitude vibrating motor | Automatic flow controller |

| Wheels with locking system | Integrated weighing system with load cells |

| Height-adjustable rotating outlet | Remote monitoring interface |

| Bilateral access for inspection | Integrated LED lighting |

| Integrated ventilation system | Integrated CIP cleaning |

| Interchangeable sieve mesh | Soundproof hood |

| Electrical protection and integrated safety | Complete hygienic fairing |

FEATURES DETAILS

High-Performance Vibrating Screening System

The adjustable-amplitude circular vibration system ensures uniform and efficient sifting across the entire sieve surface. This technology eliminates all impurities (insects, wood fragments, clumps) while preserving the flour's structure. Interchangeable mesh sizes allow you to adjust the sifting fineness according to the type of flour and the final application.

Integrated Ventilation System

The integrated aeration system oxygenates the flour during the sifting process, significantly improving its baking properties. This natural oxygenation results in a lighter, more elastic dough with better rising capacity. The outcome is a noticeable improvement in the texture and volume of the finished products.

Mobile and Ergonomic Design

The wheeled design with a locking system allows for flexible positioning within the production area. The height-adjustable rotating outlet facilitates direct discharge of sifted flour into mixers or containers. Dual-sided access simplifies inspection, mesh changes, and daily maintenance.

Areas of application

Our flour sifters are suitable for various applications in the food industry:

- Industrial bakeries - Preparation of flour for bread, pastries, and cakes

- Flour mills and flour mills - Final quality control before packaging

- Cereal industries - Sifting of specialty flours (rye, spelt, buckwheat)

- Pasta - Preparation of semolina and flour for fresh pasta

- Industrial biscuit factories - Sifting of flours for biscuits and cakes

Advantages of sieving and aeration

Improvement in the quality of finished products

Sifted and aerated flour produces more homogeneous dough with a better airy structure and a lighter texture. Removing impurities eliminates visual and textural defects in the finished products, ensuring consistent and superior quality.

Optimization of production processes

Direct integration with mixers enables complete automation of the dough preparation process. High production capacity (up to 100 kg/5 minutes) ensures a continuous supply to production lines without bottlenecks.

Food hygiene and safety

The stainless steel construction and hygienic design facilitate cleaning and meet the strictest sanitary standards. The removal of impurities reduces the risk of contamination and improves the safety of finished products.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.